Project: St. Eustatius SPM

Project Type: EPCM

Client: NuStar Energy

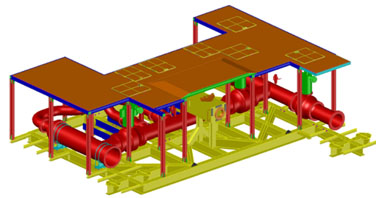

The Jukes Group completed a large EPCM project of a SPM buoy system in St. Eustatius in the Netherland Antilles for NuStar Energy. The project consisted of designing and installing two new 36-inch diameter 6,000ft long pipelines, a new 180 Tons subsea PLEM, tie-in spools and a control umbilical system for remote subsea valve control.

The Jukes Group performed the pre-FEED study, FEED, Detailed Engineering, and Procurement & Installation oversight for the project. Procurement support involved procuring the pipe, the PLEM & spool material, the umbilical, and the Onshore Valve Control Skid.

During the construction and installation phase The Jukes Group had Engineers mobilized to the island and were responsible for offshore installation during the execution phase. This also included the pre-commissioning of the pipeline and PLEM system.

The Jukes Group had over 25 Engineers that included pipeline engineers, riser engineers, flow assurance engineers, designers, and project and document controllers. The team prepared field drawings and reviewed calculations of the existing 48-inch flowline. The Jukes Group worked on the 5 phases of the Project for over one year, and it was successfully completed in 2018. The success of the project was due to a strong team of dedicated, capable and experienced Engineers.

Project Phase

- Phase 1 – Field Developing Plan

- Phase 2 – Basic Engineering Conceptual, Pre-FEED July 2016 to August 2016

- Phase 3 – Front End Engineering Design (FEED) August 2016 – October 2016

- Phase 4 – Detail Engineering and Design November 2016 May 2017

- Phase 5 – Procurement, Fabrication and Installation May, 2017 to May 2018

- 58,000 Man-hours

Project Scope

Engineer, Procurement and Construction support for the following,

- Two (2) 36-inch pipelines from approximately 100 feet onshore and terminate at the PLEM

- Two (2) 36-inch tie-in spools

- One (1) 48-inch tie-in spool

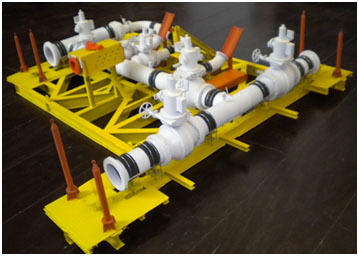

- Pipeline end manifold (PLEM)- connects both 36-inch and 48-inch pipelines with branch 24-inch pipe that connects to hoses to a SPM.

- Provided Engineering Support for Onshore and Offshore Installation Activities

Detailed Design Activities

- Project Management

- Project Controls

- Fabrication

- Document Control and Admin Support

- QHSE

- Interface Management & Onshore Support

- Procurement Support and Material Package Engineer Supervision

- Pipeline Engineering

- Umbilicals and Controls

- Engineering Drawings

- Material Selection/Corrosion/Welding

- PLEM Design Engineering

- Specifications, Philosophies and Plans

- Onshore Installation Support

- Offshore Installation Support

- Flow Assurance Support

- HAZOP/HAZID

Pipeline Analysis Activities

- Pipeline Wall Thickness Analysis

- Pipeline Stability Analysis

- Pipeline Allowable Span Analysis

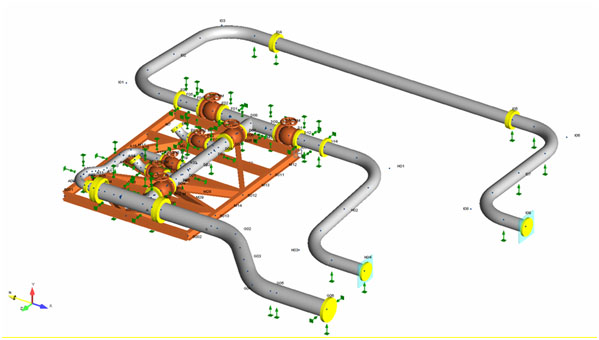

- PLEM Piping and Spool Piece Stress Analysis

- Pipeline On-Bottom Roughness Analysis

- Pipeline Thermal Expansion Analysis

- Pipeline Cathodic Protection Design

- Dropped Object Risk Analysis

- PLEM Seismic Analysis

- PLEM Design Analysis

- Pipeline Installation Analysis

PLEM Piping Stress Analysis

Finite Element Analysis was undertaken of the subsea PLEM, Piping, and Pipeline spools to determine the stress within the structure.

Procurement Support

- Linepipe and Coating

- Valves

- Anodes

- Induction Bends

- Flanges and Fittings

- Onshore Controls Skid

- Subsea Controls – H and E

- Umbilical

- PLEM Fabrication Contract

- Pipeline Installation Contract

The Project Team