The Technology and Engineering Group cover the energy sector, and this includes both oil & Gas and renewables. The Senior Engineering Team have about 850 years of accumulated experience and are world leading experts in their respective fields. We have expertise in Advanced Engineering. The Jukes Group covers Onshore & Facilities, Offshore SURF, and Topsides.

- Consultancy

- Advanced Engineering

- Engineering

- Technology Innovation & R&D

- Special Studies

- Project Management

- Expert Witness

- Owners Engineer

- HSEQ

- Facilities & Topsides Engineering

- Floating Systems Engineering

- SURF Engineering

- Subsea

- Umbilicals

- Risers

- Flowlines

- Pipeline Engineering

- Structural Engineering

- Geotechnical Engineering

- Flow Assurance

- Advanced Engineering

- Construction Management

- Installation Engineering

- Materials & Corrosion

- Offshore and Onshore Pipeline Engineering

- Onshore Facilities

- Integrity Management

- Risk Based Inspections (RBI)

- Offshore and Onshore Flow Assurance

- Economics / Feasibility Studies

- Pre-FEED & FEED

- Detailed Design

- Installation Engineering

- Start-Up & Commissioning

- Operate and Maintenance Support

- Integrity Management

- Decommissioning

- Subsea Trees (Production & Injection Trees)

- Flowlines & Jumpers

- Flow Assurance

- Subsea Processing (Separation, Multiphase Pumping)

- Commingling & Injection Manifolds

- PLETs, PLEMs & Tie-In Sleds

- HIPPS & Control Systems

- Risers

- Riser Bases

- Mid-Water Arches

- Umbilicals

- HP/HT Developments

- Engineering Support for Downhole Technologies

- Scraper Launchers / Receivers

- Flow metering

- Export Pipelines & Shore Approaches

- Platform Interfaces

- Finite Element Analysis (FEA)

- Computational Fluid Dynamics (CFD)

- Fluid Structure Interaction (FSI)

- Systems level structural analysis.

- Local and component analysis.

- Soil / structure interaction analysis.

- Soil / pipe interaction analysis.

- Impact and blast analysis using explicit FEA simulations.

- Flexible pipe and umbilical FEA using substructure (super element) method.

- Stress, vibrational and thermal analysis.

Software Packages used : ABAQUS, ANSYS, Star CCM, Acusolve Hyperworks

- Onshore & Offshore Pipelines

- Risk Based Inspection (RBI)

- Risk Based Integrity Management (RBIM) for Onshore Pipeline

- Rigid and flexible flowline analysis

- On-bottom Stability Analysis

- Expansion Analysis

- Lateral and Upheaval Buckling Analysis

- Spanning and VIV V. Fatigue

- Installation

- Mechanical Design

- Stress and Limit State Based Design

- Single Pipe and Pipe-in-Pipe

- Field Layouts

- Flowline Component Design (Bulkheads, Buckle Arrestors)

- Jumpers

- Installation Engineering

- Offshore Pipeline Supervision

- Pipeline Remediation

- Steel Catenary Riser (SCR), Top Tensioned Riser (TTR), hybrid, drilling, flexible and umbilical analysis using ABAQUS

- Global strength.

- Wave fatigue (using 1st & 2nd order motions).

- Vortex Induced Vibration – VIV.

- Hang-off systems design & analysis – stress joint, pull tubes, specialty joints.

- Interference / clashing.

- Routing & layout.

- Installation analysis.

- Drilling riser and wellhead analysis – wave fatigue, VIV, operability, weak point, drive off / drift off, recoil.

- Flexible & umbilical cross sectional analysis for strength and fatigue (using B-Flex & U-Flex).

- Global Analysis using Orcaflex.

- Concept evaluation, for all types of development from concept through to detailed design.

- Software capability in OLGA, PIPESim, PVTSim/Multiflash, MAXMUS, HYSIS and NATASHA.

- Pipeline Sizing

- Pressure Surge using Stoner Pipeline Simulator

- Pigging Model with Olga

- Corrosion

- Pipeline Leak Protection

- Onshore and Offshore

- In-place and installation (structural) analysis of jackets, jack-ups, compliant towers, floating and subsea structures.

- Strength.

- Fatigue.

- Code checks.

- Structural analysis of fixed risers and conductors.

- Piles

- Suction Caissons

- Anchors

- Subsea Foundations

- Conductor-Soil Interaction

- SCR-Soil Interaction

- Pipeline-Soil Interaction

- Centrifuge Model Testing

- Advanced Numerical Analyses

- Earthquake-Foundation Structure Interaction

- Site Investigation Planning

- Geohazard Assessments

- HAZOP / HAZID Workshops for subsea tie-backs, installations, pipeline repairs, packages, and onshore facilities.

- HSE Lead for subsea projects including HSE plans, training matrix, behavioral programs and client driven safety program and training elements.

- HSE Lead for subsea production systems at manufacturing and fabrication facilities.

- Risk registers

- Program quality support

- Design of topsides

- fixed and floating,

- Expertize in FPSO’s.

- All aspects for project execution

- Project Management

- Cost Controls

- Preparation of RFG packages

- Evaluation of bids and procedure

- Multi-disciplined Projects

- Offshore Supervision

- Global performance and station keeping

- Structural Design & Modifications

- Strength & Fatigue Analysis

- Hull Concept Selection and Evaluation

- Model Testing Supervision

- Mooring analysis

- Hydrodynamics & Hydrostatic Assessments

- Metocean Evaluation

- Detailed FEA of Components

- Fixed and Floating Platforms for Offshore Wind Turbines

- Pile Design Foundation Design

- Floater Design

- Mooring & Anchors

- Project Management

- Detailed Geotechnical Design

- Structural Design

Initiatives

- BSEE Bucket Foundation White Paper

- Alliance with Universities

- Alliance with an Offshore Wind Company

- Stack-up and tension optimization

- Operability envelope analysis

- Drift-off and drive-off analysis

- Deployment/retrieval analysis

- Riser, conductor and casing deployment/retrieval analysis

- Riser recoil analysis

- Disconnect and hang-off analysis

- Wave and VIV fatigue analysis

- Weak point analysis

- Transit analysis

- Landing string design and verification

- Vessel uptime assessment and rig selection

- Failure Analysis

- Riser wear analysis

- Drill string contact and wear assessment

- Jackup site-specific assessment

- Wellhead fatigue analysis

- Fracture and fatigue crack growth (ECA) analysis

- Failure Analysis

- Drillstring Analysis

- Jarring Analysis

- Stuck Pipe Analysis

- Piping Design

- Facilities

- Materials

- Integrity Management

- Blast & Explosion Analysis

Capabilities

- Project Management

- Risk & Interface Management

- Process

- Mechanical

- Piping

- Civil/Structural/Architecture/GeoTech

- Electrical & Instrumentation

FEED, Detailed Design

Software

- Primavera 6 for monitoring the progress of the project

- HYSIS

- Cad Works

- STAAD 3

- AutoCAD

- Caesar II

- Abaqus for seismic and foundation design

- Engineering

- Procurement

- Construction

- Gas Processing

- Feasibility Studies

- Technology Evaluation

- Technical Audits

- Process Equipment Optimization and Selection

- Basic Design

- Project Specifications Development

- Permitting Support

- Hydrological Modeling

- Remote Sensing and GIS Application

- Flood Plain Planning and Management

- Master Drainage Planning

- Flood Mitigation Planning and Benefit/Cost Analysis

- FIS & LOMR

- Water Resources Management

- Flood Control Facility Design

- Water Resource Reclamation and Water Re-use

- Grant Applications

- Clients Include all Branches of the Military, DOE,GSA, EPA, FEMA,USACE, NASA

- Technical Operations & Management Services

- Homeland Security

- Facilities Design

- Disaster Relief Support

- Environmental Studies & Remediation

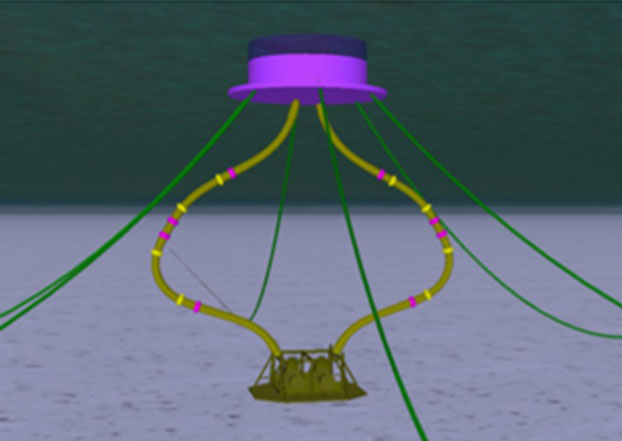

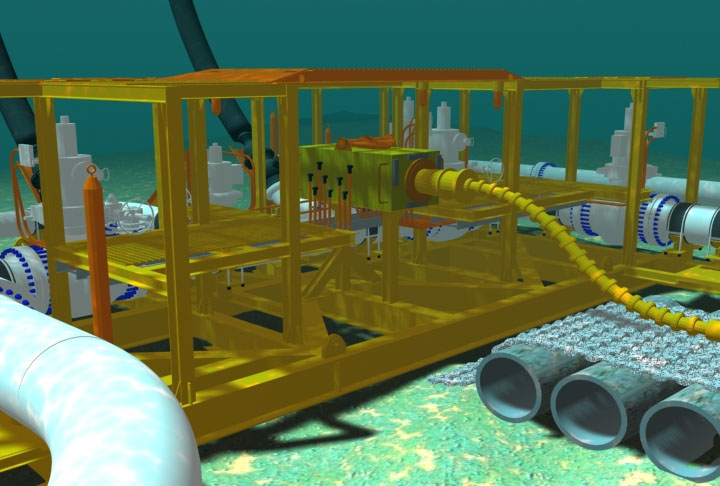

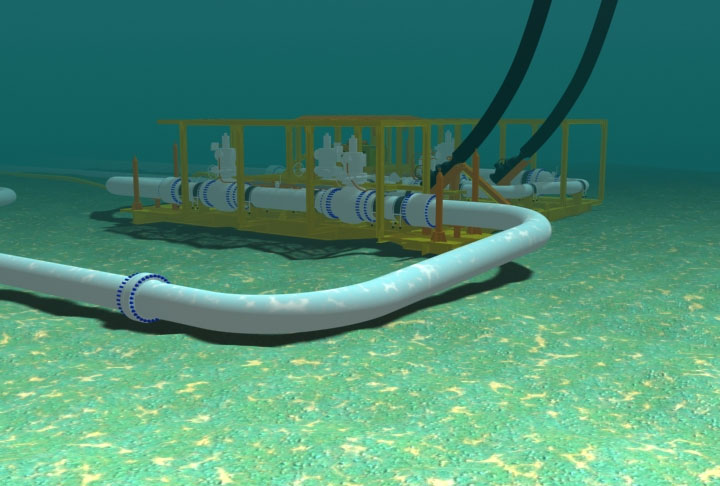

SBM and Mooring – The Jukes Group Engineer team has extensive experience in the design, analysis and Engineering to offshore loading terminals, SBM and Mooring, and Buoys. The capability includes the design of subsea pipelines, subsea PLEM structures, riser systems, buoy design, hydrodynamics, flow assurance, control systems and floating hose analysis. This includes work scopes from Conceptual studies, FEED, Detailed Design, Fabrication and Installation oversite. Also, Operational Support can be provided.

The Jukes Group team has experience on the following projects:

St. Eustatius SPM, EPCM, NuStar Energy. The Jukes Group completed a large EPCM project of a SPM buoy system in St. Eustatius in the Netherland Antilles for NuStar Energy. The project consisted of designing and installing two new 36-inch diameter 6,000ft long pipelines, a new 180 Tons subsea PLEM, tie-in spools and a control umbilical system for remote subsea valve control. The Jukes Group performed the pre-FEED study, FEED, Detailed Engineering, and Procurement & Installation oversight for the project. Procurement support involved procuring the pipe, the PLEM & spool material, the umbilical, and the Onshore Valve Control Skid. The Jukes Group had over 25 Engineers that included pipeline engineers, riser engineers, flow assurance engineers, designers, and project and document controllers.

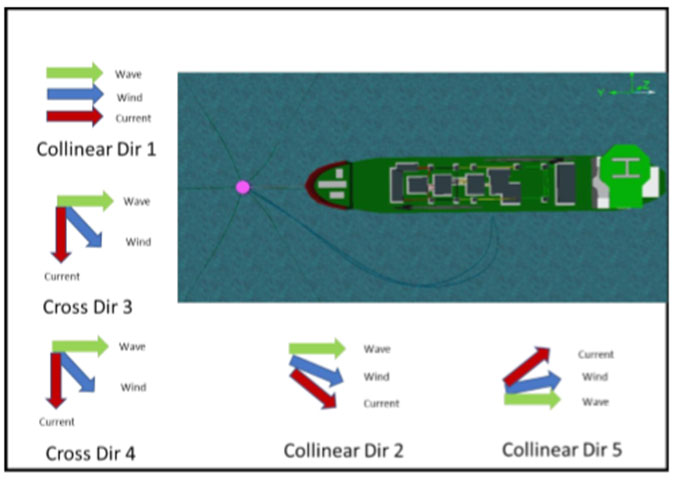

Jamnagar SPM-1, Floating Hose Analysis, Yokohama. Reliance Industries Ltd. contracted the Yokohama Rubber Company to replace the floating hoses for the Jamnagar SPM-1 CALM buoy. Yokohama contracted ETA International to analyze the suitability of the new floating hose string for the Jamnagar site using OrcaFlex software. ETA International contracted The Jukes Group to undertake the analysis. The Jamnagar SPM-1 buoy site is located in the Gulf of Kutch, approximately 11 km northwest offshore from Jamnagar, India. The buoy is a round, turret type for single point mooring (SPM), with two floating hose strings. The SPM-1 CALM buoy was subjected to “collinear” and “oblique” environmental cases of wind, waves and current that represented maximum Operational and Survival METOCEAN conditions.

NES Hose project (Brunei HengYi Project CDSR’s Hose Analysis). TJG has been subcontracted by hose supplier, CDSR to perform the integrity check for the CDSR hoses. TJG has performed strength and interference analysis to assess the suitability of these hoses to be used for SPM at PMB facility. Hengyi Industries Sdn. Bhd. (HYBN) HYBN is planning to build a Single Point Mooring System and subsea pipeline to import the crude oil and condensate oil required by petrochemical refinery plant. The water depth at and around single point moored buoy is 33m, which will allow the oil tanker of 300,000DWT class to berth and transfer fluids to and from between the SPM system and the tanker. Floating and submerged hoses are utilized to connect the SPM with the tanker and PLEM respectively. The crude oil in the tanker will be transported to the land storage and transportation facilities through approximately 8.7km subsea pipeline, connected to the PLEM.

Past SPM Terminal Experience, by the Engineering team, includes the following:

- Brunei Shell Petroleum – FEED for Seria Crude oil Terminal

- Pertamina – Submarine & Floating Hose Specifications

- ONGC & Reliance – Submarine and Floating Hose Analysis

- NuStar (Caribbean) – EPCM of pipeline & PLEM systems

- Oil Terminal Facilities Feasibility Study, Romania – Preparation of feasibility study for the modernization of the oil terminal facilities at Constantza Port.

- Client (Confidential) – Product Storage & Loading Facilities Preliminary Design, Central Africa – Prepared preliminary designs for product storage and loading for propane and butane LPG and stabilized condensate facilities for a new export terminal.

- Kuwait Oil Co. – Storage & Loading Facilities – Review of specifications for storage and loading facilities for single point mooring terminals.

- Project Manager & Engineering Lead. Cochin Port Trust, Supertanker Oil Terminal for Crude Unloading and Product Loading, and Fertilizer Berth. Detailed engineering and preparation of tender documents and their evaluations for the two port facilities.

- Indian Oil Corporation, Crude Oil Subsea Pipeline & SPM Terminal, Gulf of Kutch – Conceptual and detailed engineering to Construction management of the crude oil import subsea pipeline & single point mooring terminal.

- Engineering Lead. Oil and Natural Gas Commission – Various Offshore Development Projects. Design review and engineering of submarine pipeline systems. Installation supervision of submarine pipelines, risers, and Single Buoy Mooring.

SPM and Pipeline Previous Project Experience